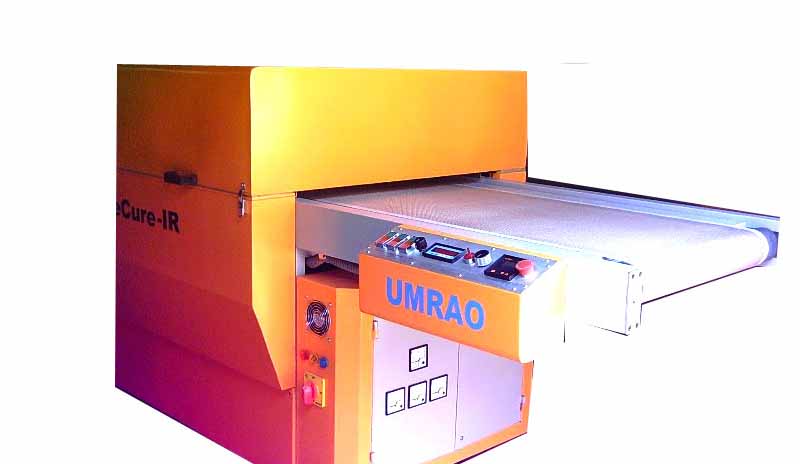

IR CURING MACHINE/ DRYER

What is Infrared Dryer? – Infrared drying (IR) uses the energy from IR radiation to directly heat the bulk material of the polymer granule/flake. The delivered energy is applied directly to the granule with no other transfer medium.

How does an infrared hair dryer work? Conventional dryers use longer wavelengths and directly dry the surface of the hair, while infrared heat warms objects from the inside out. Negative ions present in the heating process break up water molecules present in the hair, leading to quicker dry and less damage.

Backed with a team of professional and experts of the industry, we are involved in offering IR Curing Machine/ Dryer with digital control electronics. Used to keep the high-quality wooden furniture or expensive parquet flooring fascinating for a long time, their coverings need to be elaborately prepared and sealed. In long methods that are often repeated, fillers, varnishes or paints are used to the surface of the wood and cured layer by layer. This IR Curing Machine/ Dryer machine works with the safety purpose also, our IR curing unit and conveyor speed are integrated with each other. Moreover, the Teflon coated, antistatic (PTFE) belt of unit shield for corrosion and ensure longer service life. In addition to this, our offered machines are safe and economical, today’s technologies open a new world of creativity for the customers, providing a durable, protective coating as well as giving graphics an enhanced luster, depth and reality. The offered machines are manufactured using optimum quality components and advanced technology in compliance with industry standards. In addition to this, our quality experts test this product on different quality parameters. These are designed with utmost precision by our experts using advanced machines and production techniques. Apart from this, we make sure that our range undergoes quality testing phase so that our customers get the best product at affordable prices.

Description

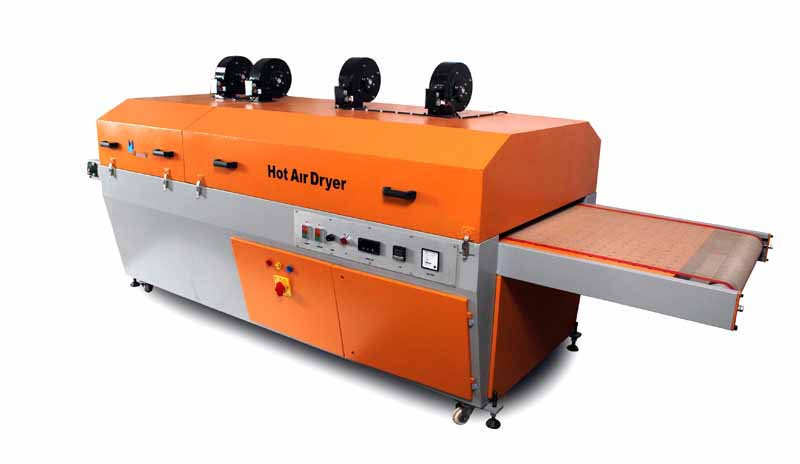

Standard Features:Air Handling

- Forced airflow accelerates drying/ curing

- High-volume circulation blower reduces energy costs

- Separate dedicated blowers for circulation & exhaust

Control Center

- After the dryer has been turned off, the blowers and belt will continue to run for 5 minutes to shut down automatically after cooling of heat chamber.

- Digital keypad with digital display

- Temperature precisely controlled by PID.

- Air-cooled electrical control cabinet ensures long life of electrical components.

Conveyor System

- Conveyor belt is made of imported antistatic heat-resistant, Teflon-coated fiberglass coating.

- Conveyor driven by a reliable, heavy-duty, variable-speed AC motor with imported variable speed drives & gear box.

- Rubber lining roller for belt.

- Minimum belt speed: 0.8 mtr per min.

- Conveyor speed & IR system are integrated with each other for safety purpose

Technical Data

| Model No | US – IR 20 | US- IR 25 | US – IR 30 | US – IR 40 | US – IR 50 |

| Conveyor Width | 20″ | 25″ | 30″ | 40″ | 50″ |

| Curing Speed | 8-12 Mrt / min | 8-12 Mrt / min | 8-12 Mrt / min | 8-12 Mrt / min | 8-12 Mrt / min |

| Cooling System | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) | Twin Blower Type (Independent blower for suction & delivery) |

| Electric Power | 9 KW | 10.5 KW | 12 KW | 14.5 KW | 16 KW |

Reviews

There are no reviews yet.